Solutions

Tortillas, Pizza and Doughs

Maximize yields, reduce costs and waste.

Vision Inspection of Tortillas, Pizzas and Doughs

Producers must ensure that their lines are energy and labor efficient, as well as capable of producing high yields with minimal waste. A Montrose inspection system can provide invaluable process data about your product’s visual characteristics, and at the same time reduce your labor requirements.

Montrose vision and handling systems provide a complete inspection, individual fault rejection and handling solution created specifically for tortilla, pizza crust, pita, pancake, flatbread, topped pizza, and dough producers. Receive comprehensive statistical analysis of variability while removing human involvement from inspection, rejection, counting, and grouping.

Montrose inspection software is easily configured to include your specifications and to continuously monitor for all product attributes and faults that are most important to you. Systems are designed to fit off-line or in your production line, to suit your bakery environment, and exceed your hygiene requirements.

Inspection System Measurement Capability

Whether you want to sample or provide 100% inspection, Montrose Technologies has a solution to match your application.

Benchtop

The complete, stand-alone SnapQC™ system uses a high-speed, non-contact imaging method to capture a wide range of object information such as color, height, diameter, slope, symmetry, length, volume and weight.

In-line

The MT-Series™ of in-line systems allow 100% inspection with top and bottom color and a full set of rejection options. The systems are easy to use, sanitize and have a low annual maintenance cost and provide real-time data for operators.

Over-line

FocalPoint™ over-line systems can be incorporated into an existing production line. They are easily installed, versatile, low-cost turn-key solutions for continuous inspection which provide real-time data for operators.

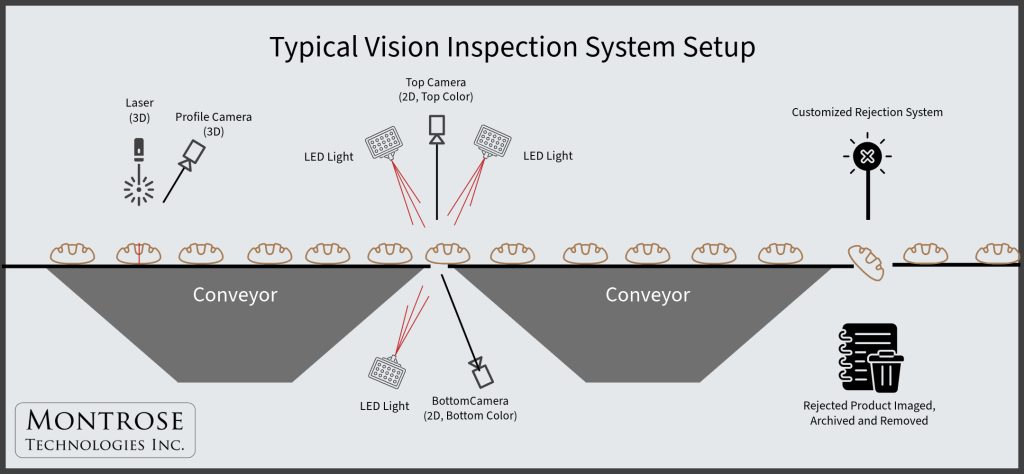

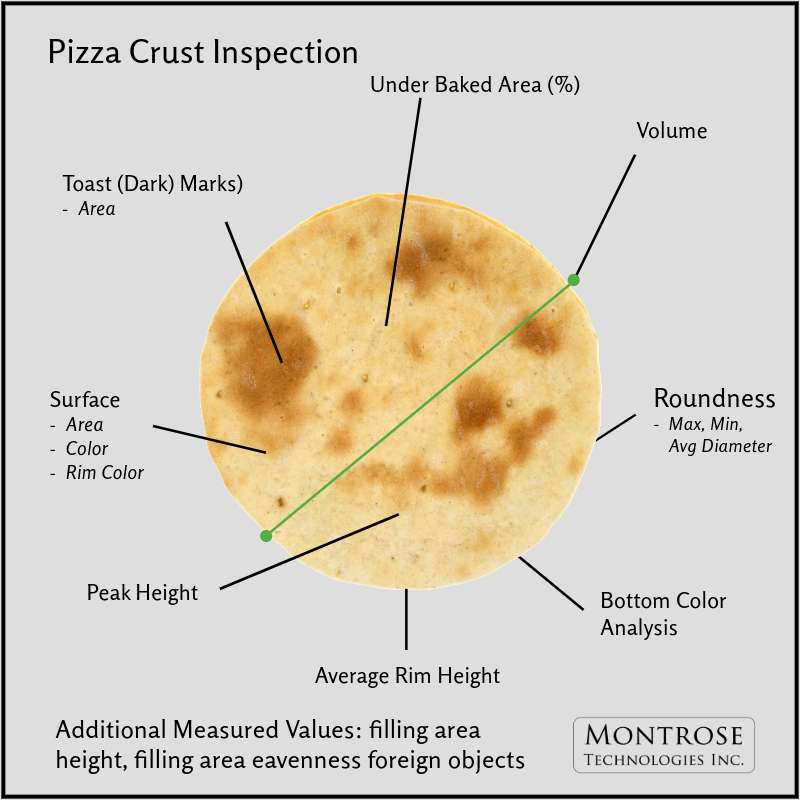

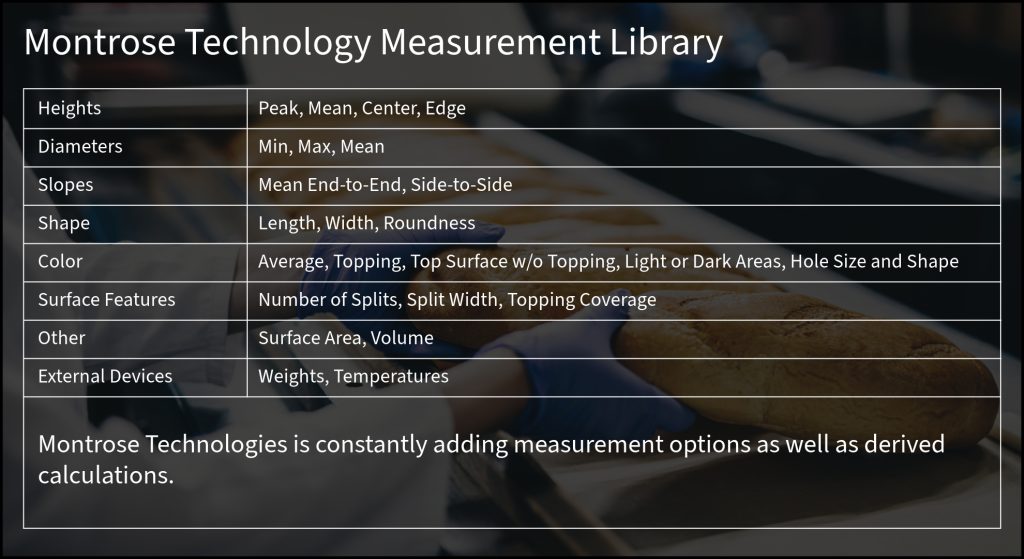

Types of Analysis and Rejection

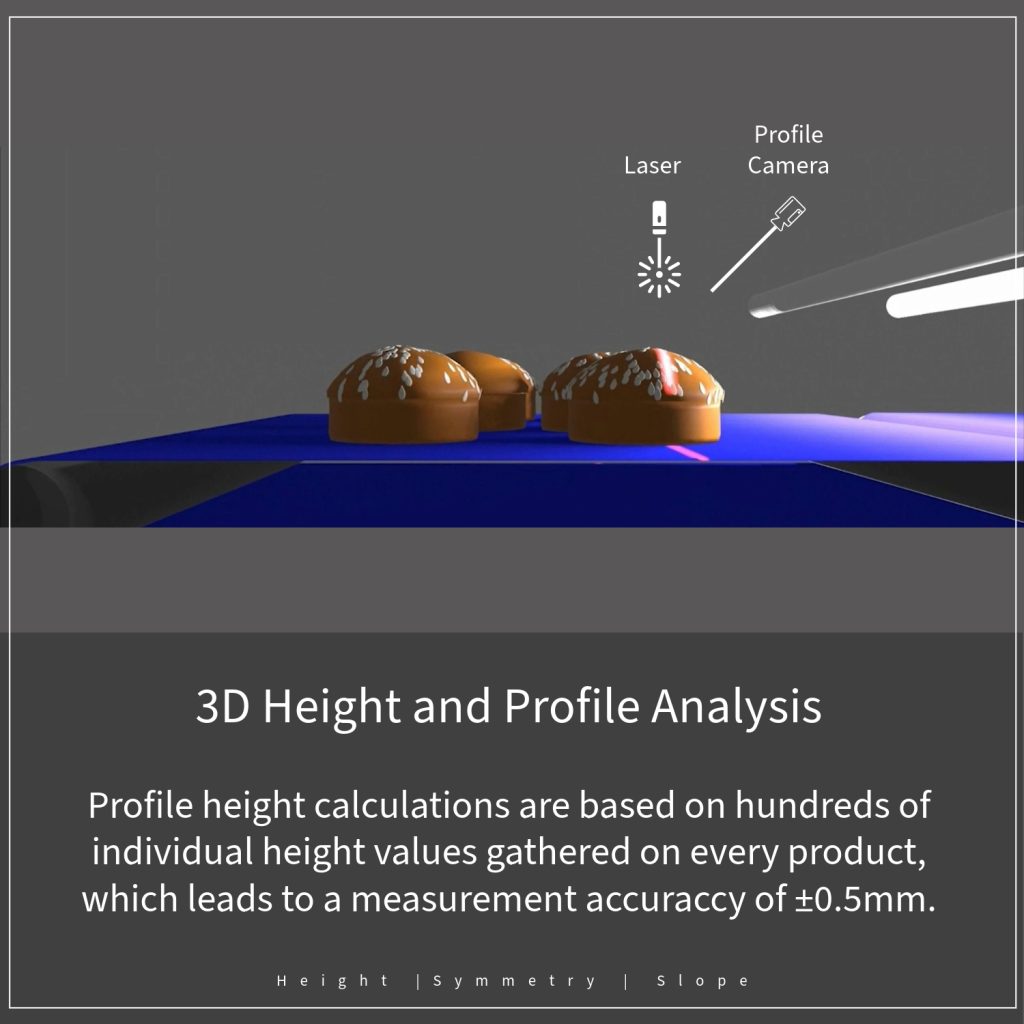

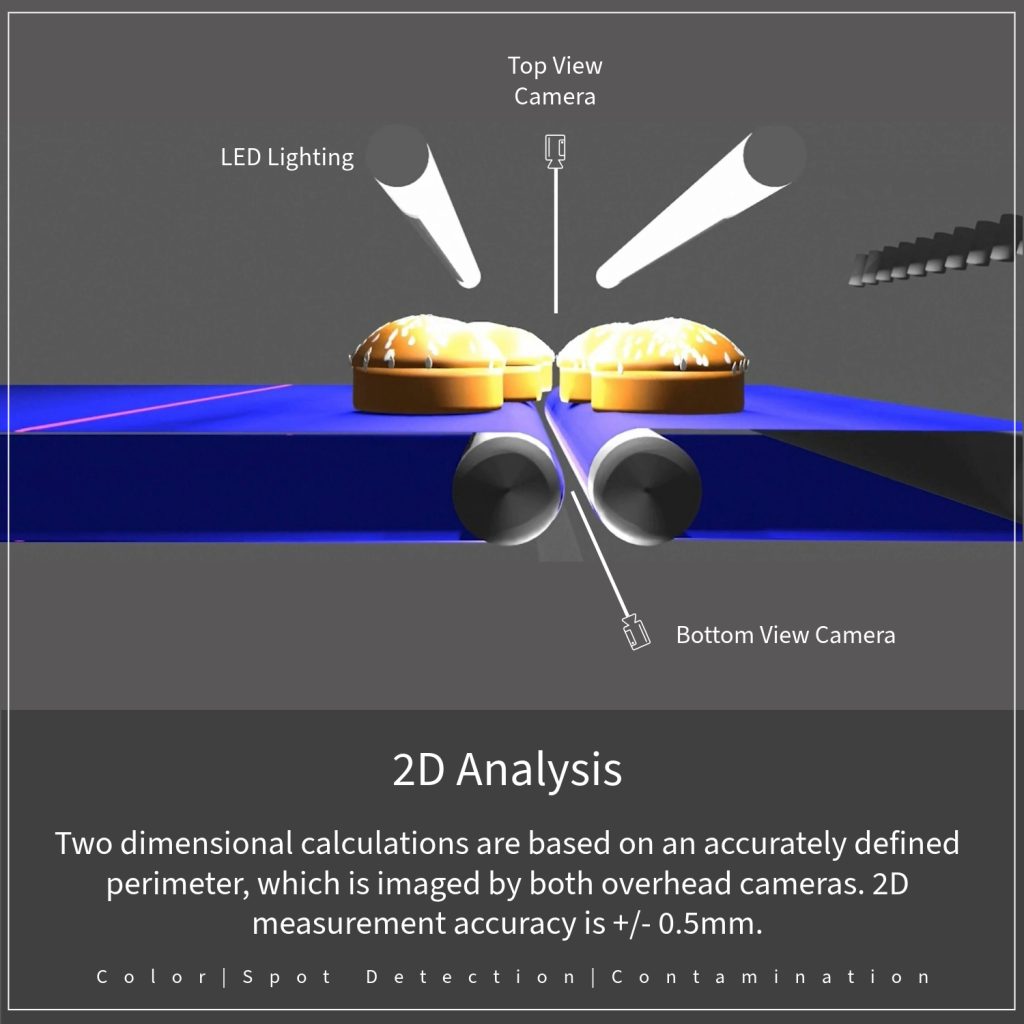

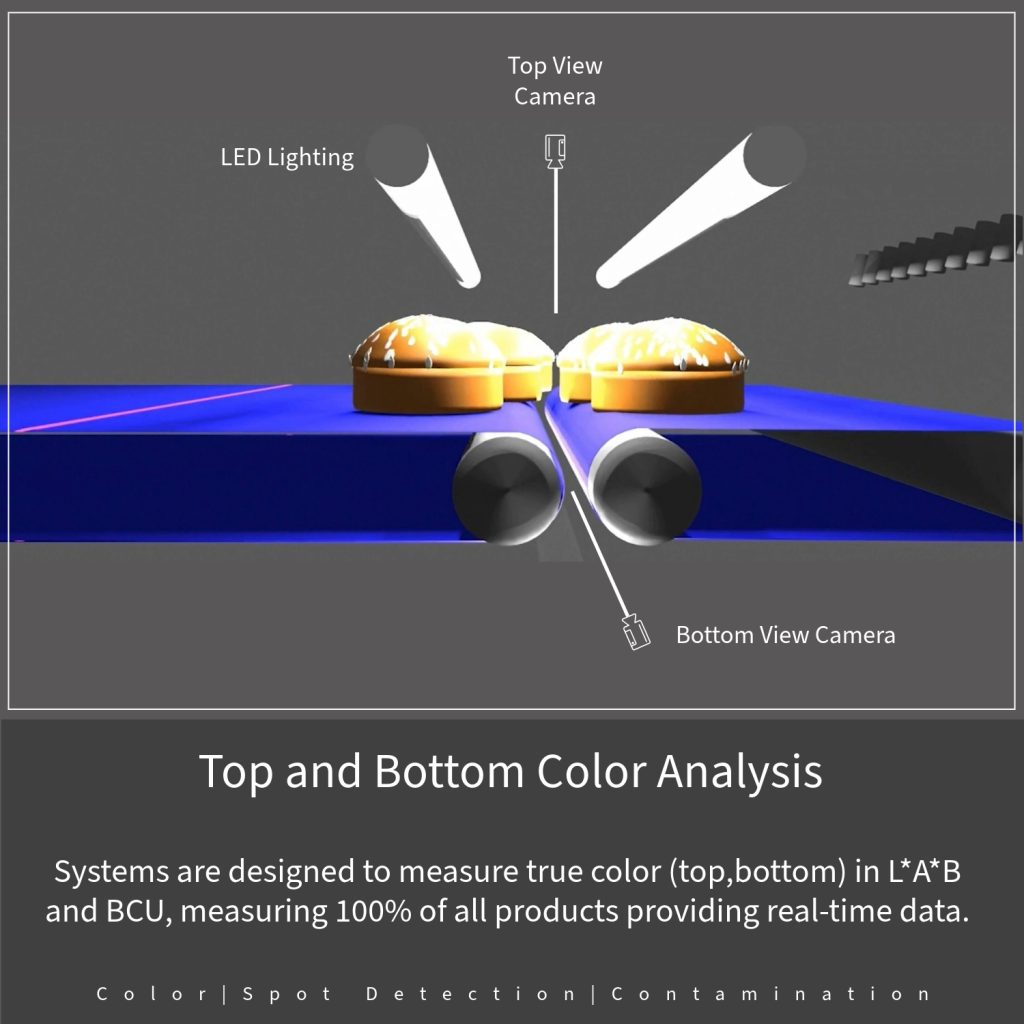

Vision inspection systems employ high-speed cameras and lasers in combination with Montrose imaging software to detect and measure randomly oriented and sized objects on a conveyor belt. Data from the laser and imaging devices produce 2D, 3D and color information which is fed into the analysis software. LED lighting systems are designs with the specific product the system is analyzing to ensure the most efficient imaging occurs. Each system, whether benchtop, in-line or over-line, is designed along the same principles. The laser and profile camera produce the three-dimensional information while the separate top and bottom camera perform the two dimensional and color analysis.

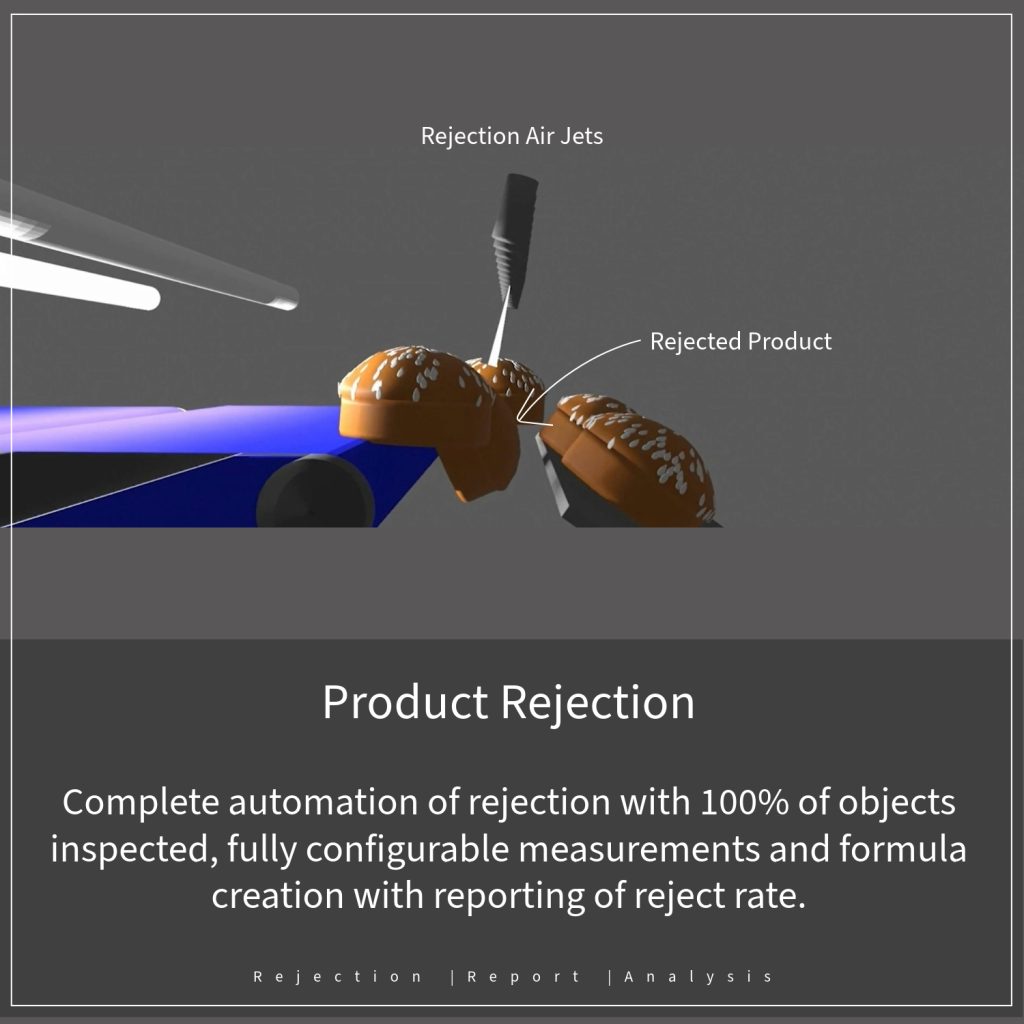

Rejection systems vary between systems and product types and are designed according to customer specification. Montrose develops and manufactures a complete set of solutions for the baked goods and snack food industry.

3D Measurements

- Profile height calculations

- Slope

- Mean height

- Peak height

- Center height

- Side-to-side slope

- End-to-end slope

2D Analysis of Shape

- Mean diameter

- Maximum diameter

- Minimum diameter

- Surface Area

- Volume

- Roundness

- Width/Length

Top and Bottom Color

- Top average color

- Bottom average color

- Area missing topping

- Topping % area covering

- Split width

- Light and dark area

- Hole size and shape

Rejection Features

- Reject rates by cause with fault type and alarm

- Rejected product displayed to operator and imaged

- Generate Pareto charts

- Rejection settings are configurable

Vision System Components

In-line and Over-line Inspection

The type and size of food product transported through the vision system will determine the number of cameras needed for the measurement requirements, the individual product rejection method, and hygienic/environmental considerations. Furthermore, vision inspection systems may include other customized material handling solutions such as automatic de-kissing of product, automatic box loading, and multi-route sorting.